HD Vinyl Pioneer, Guenter Loibl talks to Sound Matters about his ambitions to revolutionize vinyl record manufacturing using lasers.

The HD-Vinyl concept first caught our attention back in 2016, when Austrian-based company, Rebeat first filed the patent for a new vinyl record production process involving lasers. Naturally, it wasn’t long before the internet was awash with speculation about the new technology and its possibilities. Earlier this year, HD Vinyl moved a big step closer to market release with the announcement that Rebeat had successfully secured $4.8 million in funding. To learn more, we talk to Guenter Loibl, the man behind an ambitious company that seeks to transform vinyl manufacturing.

SM: Vinyl production hasn’t changed much since sales peaked in the 1970’s. Why change the process now?

GL: As the French poet, Victor Hugo once said: “Nothing is as powerful as an idea whose time has come.” …and it is definitely time to bring vinyl production into the 21st century.

The need for a new way to produce vinyl became apparent to me during meetings with labels, for which Rebeat distributes digital music. Almost every time, someone would complain about the lead time on vinyl record production, which can be as long as six months. Also, when you finally receive the records, quality is often inconsistent and can vary from one record to the next. As it turned out, the reason behind this is the outdated way of producing stampers. So I asked myself “Why not use a laser to cut the stamper?”

SM: Which problems exactly does HD Vinyl seek to fix?

GL: HD Vinyl is nothing short of a revolution of the way record stampers are produced. Traditionally, a master disk is cut out of a lacquer surface which is then coated in silver and electroplated (a highly toxic process). The resulting negative copy is called the “father,” which also is electroplated to produce the “mother,” which then is electroplated to achieve the “son,” which is finally used for pressing. Essentially, a record is a copy of a copy of a copy.

HD Vinyl stampers, in contrast, are cut out of a ceramic plate with a high precision laser, and the records are pressed directly from this original. No more audio-loss with every copy, no more toxic chemicals, and, greater quality control.

Pressing plants can produce records faster and with more consistent quality; they also save money on work safety and the disposal of toxic waste. This new, more modern production method is compliant with existing and possible future environmental regulations.

SM: So there are clearly plenty of production gains. Are there any benefits for the consumer?

GL: Many. You see, right now quality deteriorates with every pressed record. After a maximum of 1,500 pressings, the stamper is worn down and needs replacing. With a ceramic stamper, you can press 10,000 copies, and every copy from the first to the last will retain the original high quality.

Another benefit is that you get the most precise reproduction of the recording possible. The reason for this is that, unlike a lathe, the laser will not overheat, and thus cuts finer structures – increasing the maximum high-frequency from 20KHz up to 100kHz. This means that you no longer lose any overtones.

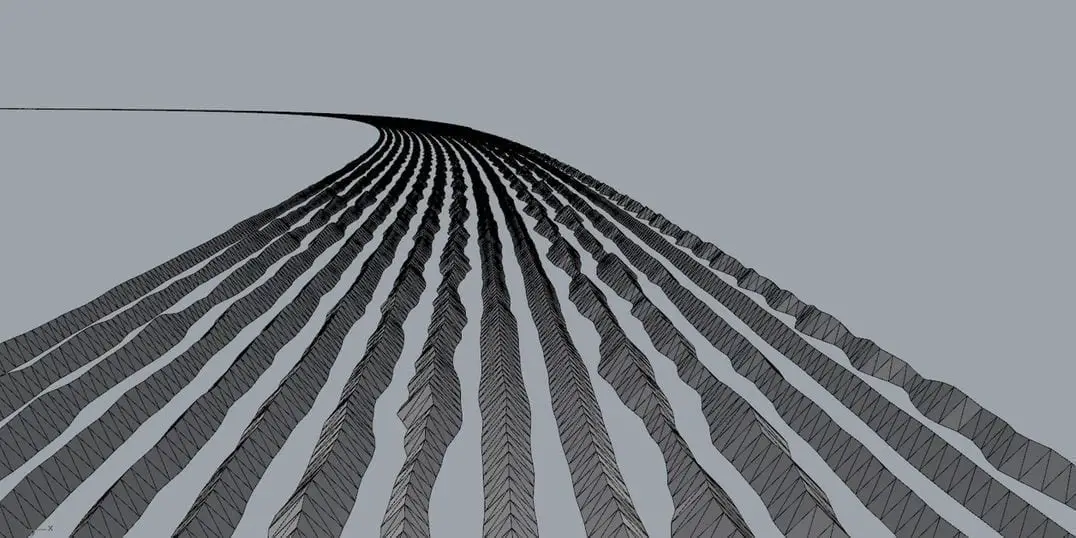

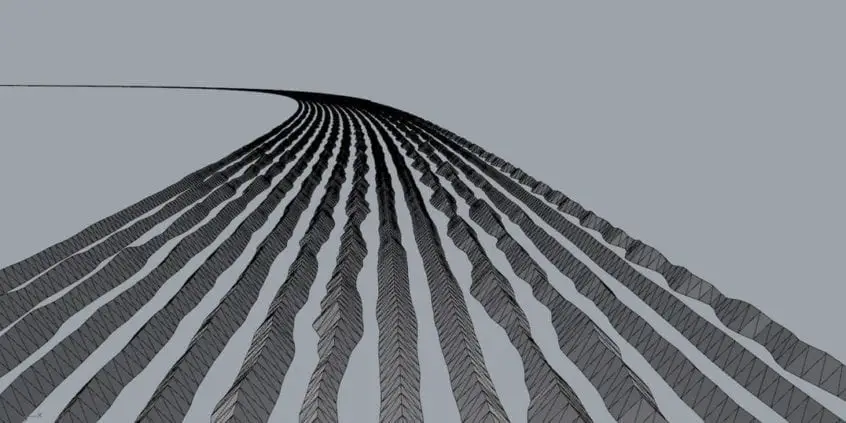

Moreover, you get a perfect groove with better dynamics, improved signal-to-noise ratio, and longer playback time. How? In order to cut the stamper with a laser, we convert the digital audio file into a 3D topography. This gives us the opportunity to optimize the space between the grooves freeing capacity for more audio-information. We can even remove the tracking error from both tangential and radial payback systems by factoring that in.

SM: By using a digital audio file, how does HD Vinyl genuinely relate to analog media?

GL: What most people do not realize is that 90% of all recordings are digital anyway. So when you listen to a new vinyl today, the chances are pretty high that it is based on a digital audio file. In this regard, traditional vinyl is no different from HD Vinyl; we simply utilize digital tools to release the full power of analog.

SM: But will HD Vinyl still carry that “warm” vinyl sound?

GL: The sound is mainly created during mastering. And the mastering process will be the same – with one difference: mastering engineers can now create (on vinyl) the most precise reproduction of a recording possible. In the end, every consumer has to decide for themselves since “warm sound” is very subjective.

SM: And what about equipment? Will consumers need a special HD Vinyl turntable?

GL: No, HD Vinyl will be 100% backward compatible and you will be able to play them with any standard turntable. Having said that, there will be special HD Vinyl turntables for those who want to get the most out of their HD Vinyl.

SM: With the average price of a vinyl record reaching a painful $30, many consumers fear that HD Vinyl will be even more expensive. Will record buyers have to pay a premium for HD Vinyl?

GL: We can only define the price for the stamper. The consumer price is determined by the labels and stores. I expect an initial price premium, which will subsequently decrease. However, HD Vinyl offers many possibilities to lower costs. For example, the extended playtime could allow labels to release a single vinyl album instead of a double. Also, costs for work safety and toxic waste disposal will decrease tremendously.

SM: HD Vinyl definitely sounds interesting. When can we expect the first HD Vinyl in stores?

GL: At the moment we are starting to produce the first test stampers, which will be used by our industry partners to develop molds for the pressing machinery. Every pressing plant will be able to switch the molds on their existing machinery in order to press HD Vinyl. Parallel to this, we are developing the software for the 3D topography. A lot to do, but we are right on track and we aim to have the first HD Vinyl in stores by the second half of 2019.

To learn more about HD Vinyl, visit hdvinyl.org

[…] down the value chain will also help us greatly to improve quality through continuous improvement, new technology like HD Vinyl, and […]

How did you get the record into the computer? Did you do a digital scan of a record or use CAD to model them? Really curious about this, would love to see the model.

[…] and excitement for music fans. I’ll be attending the Making Vinyl conference in Berlin to work on High-Definition vinyl releases for 2020. We are also launching a new record player and collectible records that come with […]

[…] as the market responds by opening new pressing plants and developing innovative technologies (HD-Vinyl is very much at the forefront of this change, as well as the increasing number of pressing plants opened in the last couple of […]